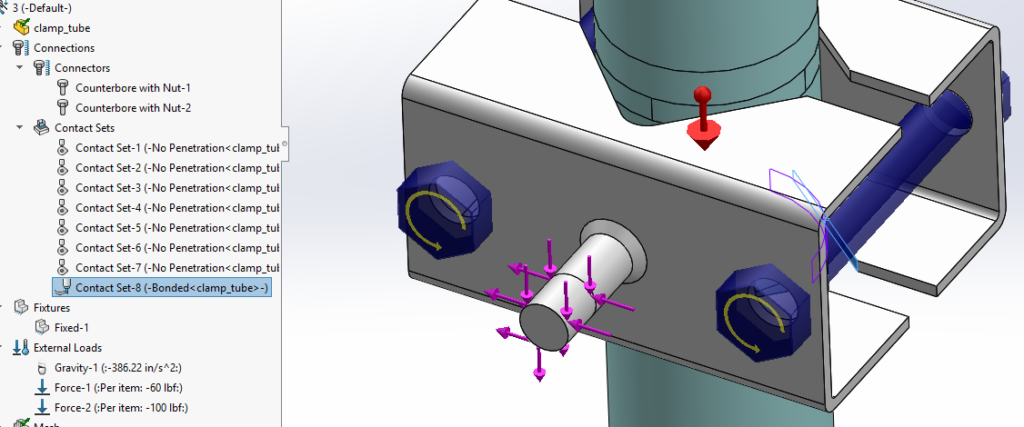

A question was recently posed in the Solidworks user forums about trouble solving a tough problem. A two-piece clamp-on bracket is bolted to itself on a length of pipe. Some live load is mounted to the bracket. The problem is trying to simulate the load on the bracket, which stays on the pipe only by friction.

I do a lot of contact analysis. I have found friction to be a tough thing for static solvers, but it does work. However, where I’ve wanted to use friction, I often realize that the objects staying together is an assumption of the problem in the first place. I’ll usually bond one contact pair, let the others slide, and go back to check resulting forces after getting a good solve.

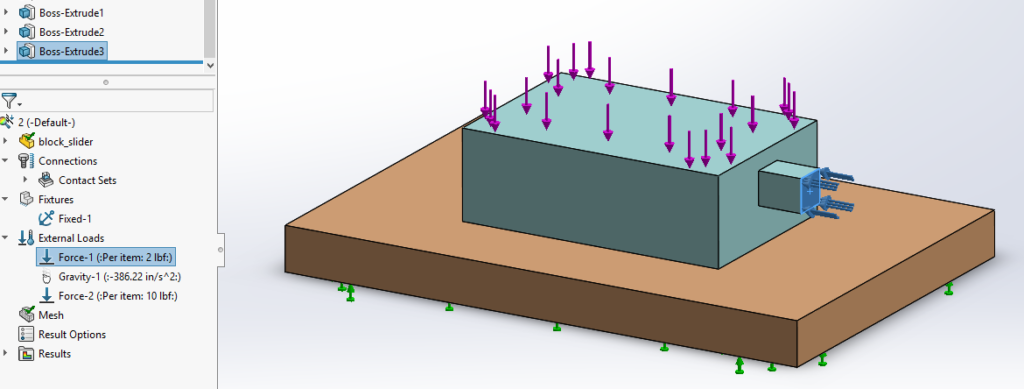

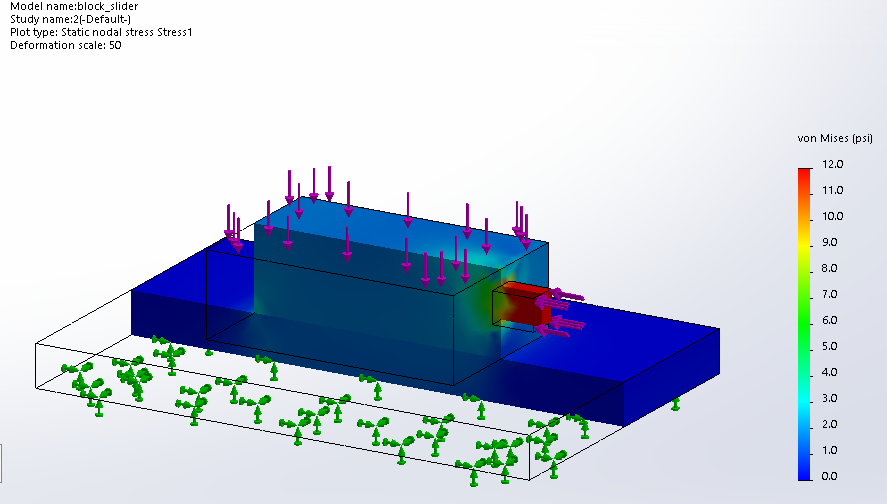

This post got me thinking and I went ahead and made a couple models to tinker with.

The first question is – Can Solidworks Simulation solve a model with friction as the only restraint on loaded bodies?

Yes is the answer.

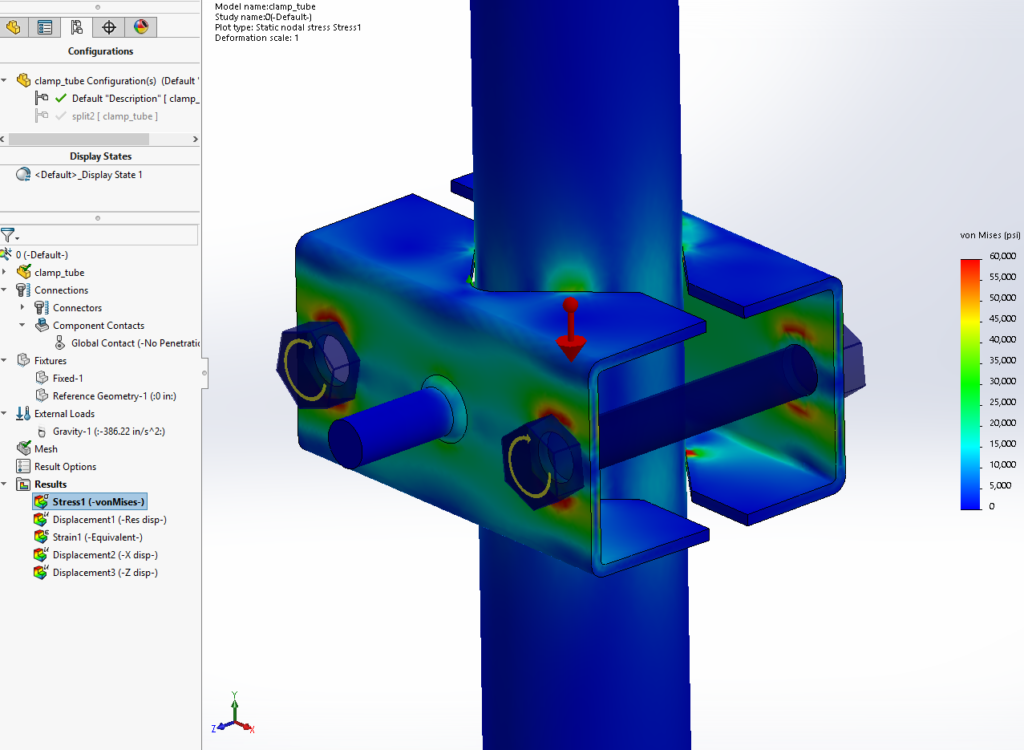

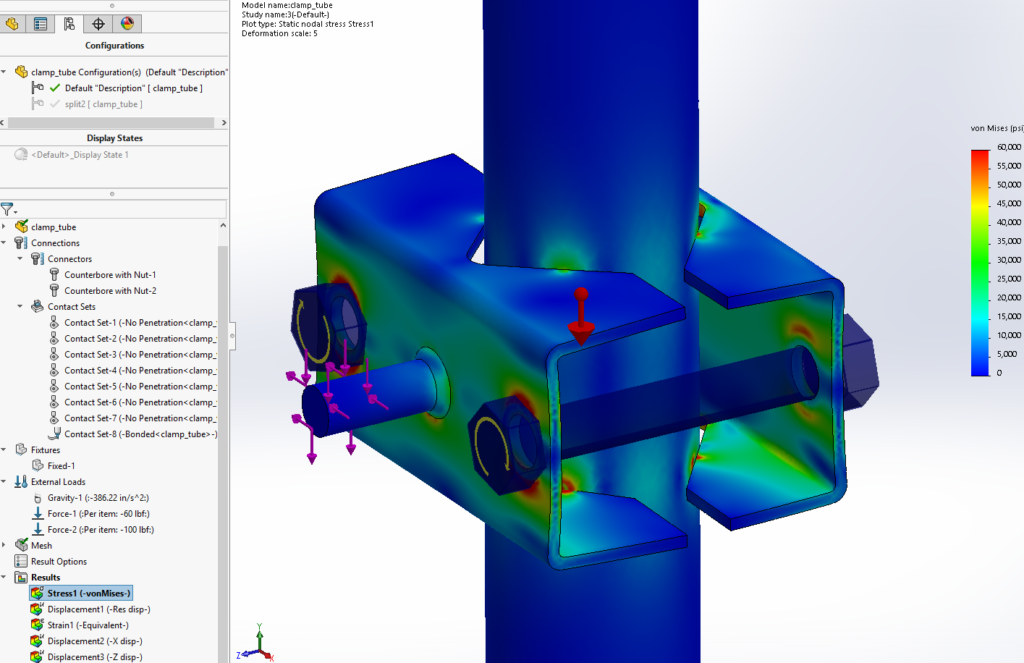

Here a bolted pipe clamp is loaded only by gravity. For stability one vertex is constrained in one plane. With a coarse mesh and global no-penetration contact it solves in a few minutes. (It’s better to split surfaces and assign contact manually in discrete pairs; that gives both more control and more information about what’s going on.)

But lets look at it another way – assume that the static friction is sufficient. If it’s not, the design has failed and the static solver cannot give an answer anyway. Remember that coefficient of friction is an input. You make it up, based on something external to the simulation.

So we bond one or more of the mating pairs.

It takes almost an hour to solve, with loads applied in addition to gravity.

The bolt preload may be too much for these shapes (half inch bolts ‘looked’ right, but here is where a series of quick simulations can readily improve a design!). But the stress pattern and deflection are totally reasonable.

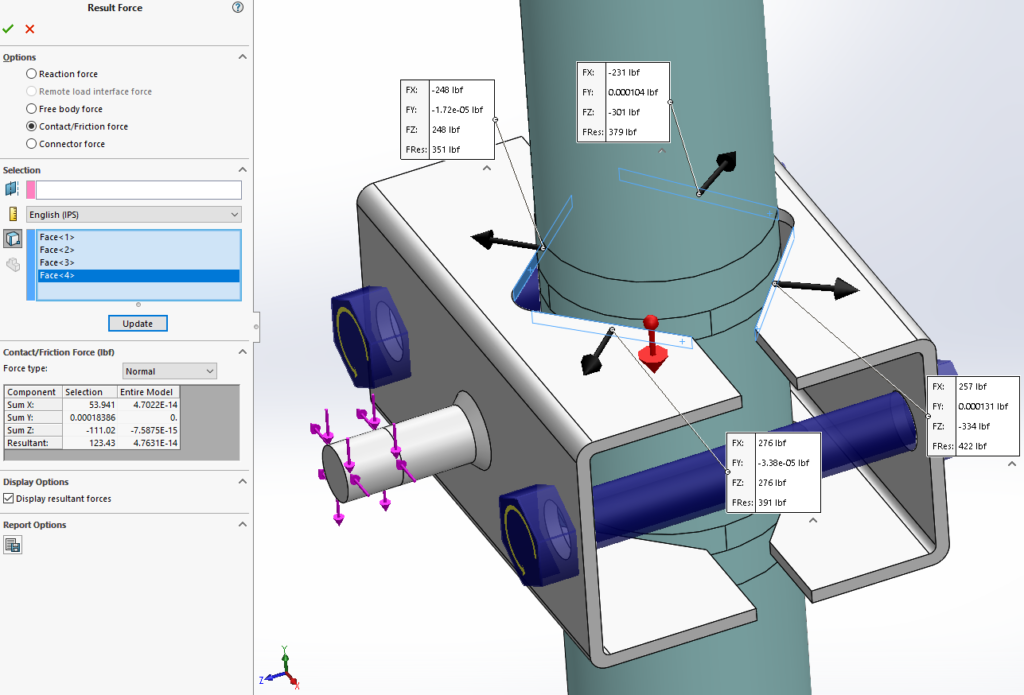

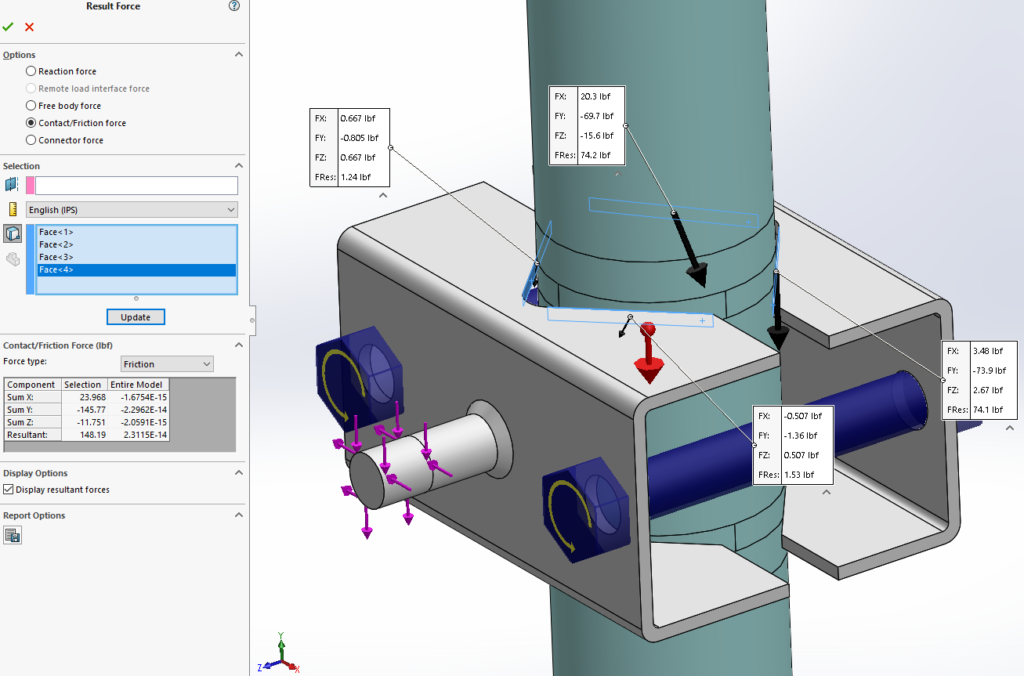

Having manually assigned contact pairs, we can check the normal and supposed friction force at each.

There might not be enough friction on the back side (at 0.2 CF). Pre-load is reduced on the front, but friction is not called for there. A similar check on the bottom four contacts shows they probably hold. But all of this depends on how good we think the friction is.

There are other way to look at this. One could put a prescribed displacement at the load, based on a best guess. What displacement? Try a fully bonded solve with live forces then use that resultant displacement.

We don’t yet have a fully ‘loose’ solution, with nothing but pure no-penetration contact. But with an honest approach we can get a much easier solution that does validate the design, if it is actually valid.